2017

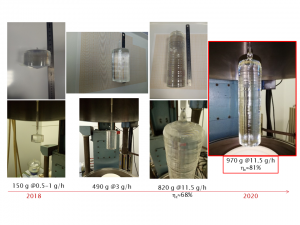

We have successfully grown 230 g Li2MoO4 single crystals by the Czochralski method in a Pt crucible under air atmosphere, within the framework of the CLYMENE project aiming at the realization of the new crystal production line for a tonne-scale double-beta decay cryogenic experiment CUPID. The crystals’ characterization demonstrates their promising properties for heat-scintillation cryogenic bolometer operation in terms of radiopurity levels (40K≤47 mBq/kg, 226Ra≤0.37 mBq/kg, 232Th≤0.21 mBq/kg, 228Th≤0.27 mBq/kg), optical transmission (αABS(589 nm)≈0.05 cm-1) and thermal properties (θD≈765 K, no phase transition down to 2 K). The thermal expansion, dilatometric and calorimetric analysis partly explains why these crystals are much easier to grow than other molybdates being developed for such applications, especially ZnMoO4. All the impurities partition coefficients in Li2MoO4 were found to be higher than 1, and the resulting melt depletion was confirmed by all the impurities concentration measurements performed in the last stage of growth. Bolometer operation firmly established that β, γ and cosmic muon events can be discriminated, as well as α-events arising from the 6Li(n,t)α reaction.

2018

Bolometric tests of two lithium molybdate scintillators (158 and 13.5 g) produced from the previous 230 g crystal boule were performed. The Li2MoO4 cryogenic detectors demonstrate possibilities to achieve a high energy resolution, particularly for 2 keV FWHM baseline noise of a small bolometer, the measured energy resolution in the energy range of 0.2–5 MeV is 2–7 keV FWHM. Thanks to high scintillation properties (one of the highest light yield, 0.97 keV/MeV, ever measured with Li2MoO4 scintillating bolometers), the coupling of a standard performance light detector (with 0.2–0.3 keV FWHM noise) to Li2MoO4 bolometers allowed to get the rejection of α-induced background on the level of 10σ. The material also exhibits potentially high radiopurity: only 1.4 mBq/kg of 210Po has been detected, while the activity of other radionuclides from U/Th chains is below 0.2–0.3 mBq/kg. Due to the observed depletion of 228Th and 226Ra during the Li2MoO4 growth, the crystal radiopurity might be further improved by repeated crystallization stages. Both performance and radiopurity are similar to the results achieved with Li2MoO4 detectors recently developed in the LUMINEU project. These results prove the prospects of the new R&D on Li2MoO4 scintillator to develop high quality large-volume crystals needed for the realization of cryogenic double-beta detectors with high bolometric and spectroscopic performance, and very low level of radioactive contamination. The R&D is ongoing to develop a 0.5 kg crystal boule with even better properties by means of combined numerical simulations and well-designed implementations of the Li2MoO4 crystals Czochralski growth process.

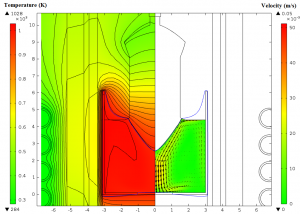

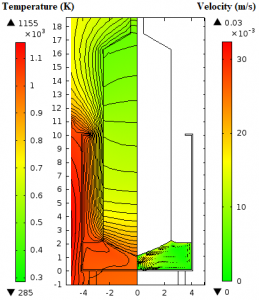

Czochralski growth of Li2MoO4 crystals 3-4 cm in diameter was numerically investigated for two inductively heated furnaces. The modelling of the first configuration (used to grow ingots of 3-4 cm in diameter) shows large temperature gradients, likely to generate high thermo-elastic stresses in the crystals. The growth process becomes unstable at the later stages of the crystallization, since the bath solidification becomes very fast and starts also from the crucible bottom. Numerical results reveal high temperatures at the free surface of the melt, which is likely to induce MoO3 volatilization. In practice, it is known that the temperature of any point at the liquid-gas interface should be better kept below. The growth of Li2MoO4 crystals of 5 cm in diameter is more difficult and requires numerical optimization of the temperature field in the furnace. Numerical results show favorable thermal conditions for the growth in a configuration which uses heat insulation between the crucible and the surrounding alumina tube. The crucible aspect ratio has been optimized in order to avoid too high temperatures at the free surface of the melt. The effect of crystal rotation on the interface shape was investigated at high rotation rates for the both configurations (ωcrystal=15-50 rpm). It is found that the crystal-melt interface cannot be flattened in this system, since the change in the flow direction underneath the crystal produces significant distortion of the growth interface. In practice, however, low rotation rates (ωcrystal=5 rpm) should be used in order to homogenize the melt temperatures in the azimuthal direction. So the Czochralski growth of Li2MoO4 crystals requires specific growth conditions as compared to other semi-transparent crystals (sapphire or langasite compounds).

2019

Crystals with 4 and 5 cm in diameter were grown in two different Czochralski configurations. The first configuration, based on inductive heating of a RF coil coupled with a platinum crucible, was used to grow crystals of 4 cm in diameter. The crystal boule 4 cm in diameter grown in the non-optimized furnace cracked during the cutting of the bottom part of the ingot. Numerical modeling was applied to investigate the temperature field in the furnace, the melt convection and thermo-elastic stresses in the crystal. Numerical results show that high thermal stresses at the bottom part of the ingot are generated by the large radial temperature gradients, and they also reveal 30% higher thermal stress at the bottom part of the ingot in the case of a concave shape of the crystal tail (experimental case) as compared to the case of a convex shaped tail. This could explain why the fracture started at the bottom part of the 230 g crystal boule, and highlights the importance of the crystal shape in the last stage of growth process. The furnace configuration used to grow 5 cm-diameter crystals was numerically optimized in order to reduce the thermal stress in the crystals. The first kg-mass Li2MoO4 ingot grown in this furnace was free of cracks and exhibited a regular outer shape.

2020

Based on our numerical simulation results, we have optimized the heating zone of our Czochralski furnace in order to prevent melt overheating or undercooling, avoid large stresses in the crystals and provide a slightly convex solid-liquid interface. We are now capable of producing routinely kg-mass Li2MoO4 single crystals with 50 mm in diameter, either [110]- or [001]-oriented in the growth direction, at a faster pulling rate (2 mm.h-1) than by the low temperature gradient Czochralski method (LTG-Cz). The crystallization mass yield reaches 81% and can still be improved. The crystals do not exhibit any twins, and the dislocation densities are in the range 0.8–1.4 × 104 cm-2 for the crystals 50 mm in diameter. The dislocations in Li2MoO4 are oriented along the [11-20]-direction and contained in the (0001) plane, corresponding to the basal glide system. This is the most common slip system found in trigonal crystals, the one that is the most energetically favorable to the gliding of dislocations. The full tensor of elastic coefficients was measured as a function of temperature by Brillouin spectroscopy, and led to estimates of the bulk and shear moduli of 48 and 18 GPa at room temperature. Hence, Li2MoO4 crystals have a low mechanical hardness which decreases when temperature increases. Besides, when uniaxial compressive tests designed to optimize the Schmid factor for the shear stress –that is, when the compressive stress direction is right between the [0001]- and [11-20]-directions, with a 45° angle from both directions-, the crystals crack without dislocation multiplication and without twin formation, at 450 and 650°C under stresses up to 10 and 7.6 MPa, respectively. With these new inputs, anisotropic stresses occurring during growth have been recalculated by finite element numerical simulation of heat transfer and thermo-elasticity, by means of the same modelling procedure as previously published but applied to the specific set-up configuration used for growing the crystals and with an [001]-oriented seed. The temperature, velocity and stress fields were calculated at three different solidification distances during the growth: at the end of the shoulder, after 3 cm of solidified distance and at the tail of the bulk crystal. The interface deflection is small (3.65 mm measured versus 4 mm calculated), and barely changes with solidification distance, which is an indication of the good thermal stability of the pulling configuration and an indication that the crystallization mass yield can be further improved. The temperature gradient in the crystal reaches a maximum of 30 K.cm-1, which is always located close to the triple phase line. In addition to interface deflection assessments by rapid extraction experiments of the growing crystal at several solidification distances, we measured temperature versus time profiles in selected points of our set-up during the growth of the crystals and also found a good agreement between measured and calculated temperatures. The velocity field in the liquid phase displays only one counterclockwise vortex, the center of which remains in the upper part of the liquid and moves towards the triple point line as solidification proceeds. The velocity decreases as solidification proceeds too, from typically umax=0.015 to 0.011 m/s. All stresses in the xz section of the crystals are now below the minimum crack formation threshold (σmin>3 MPa, σmax<7.5 MPa at 650°C), as determined from uniaxial compressive tests, and they are the strongest at the periphery of the crystal when the shoulder is formed, and in the middle of the solidification interface at further growth stages. The fact that Li2MoO4 exhibits a fragile cracking behaviour without plastic response (either by dislocation multiplication or by twin formation) is a rather uncommon feature for an ionic crystal.